Controlling Workplace Hazards

Problem: You’ve Identified a Hazard – Now What?

Your Problem: After careful inspection, you’ve identified several serious and not-so-serious hazards in your workplace. You know you need to correct the hazards, but you’re unsure where and how to begin. What’s your next step?

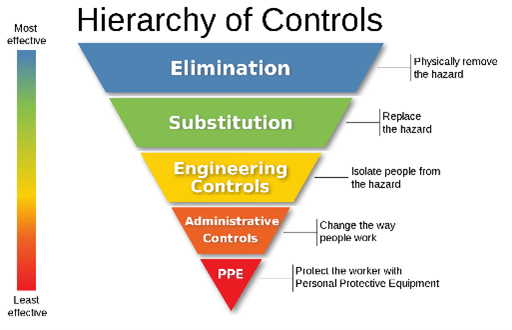

Your Solution: Use the Hierarchy of Controls to identify hazard control options. The hierarchy of controls is a method of identifying and ranking safeguards to protect workers from hazards. The controls are arranged from the most to least effective. Let’s examine each control.

Elimination completely removes the hazard from the workplace. Examples: stop using a hazardous material, work at ground level instead of at heights, stop using the process that creates the hazard.

Substitution changes out a material or process to reduce the hazard. Examples: switch to a less hazardous material, change to a process that uses less force, speed, temperature, or electrical current.

Engineering controls reduce exposure by preventing workers from coming into contact with hazards. Examples: noise enclosures, local exhaust ventilation, guardrail system, machine guards.

Administrative controls are changes to work procedures or practices to reduce the risk of exposure to hazards. Examples: trainings, procedures, policies, or schedules that lessen the threat of a hazard to workers.

Personal protective equipment includes clothing and devices to protect workers. Examples: safety glasses, hardhats, respirators, and hearing protection.

Usually, you’ll need to combine control methods to best protect workers. You will also need to determine whether each control is feasible–possible to do easily or conveniently–in your workplace.

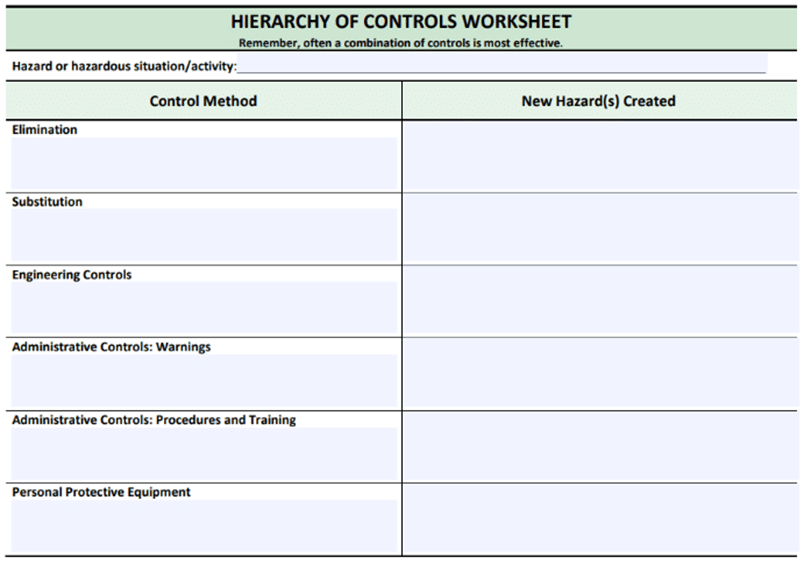

Make It Happen: Together with the affected workers, you should brainstorm your way through the hierarchy of controls for each workplace hazard you’ve identified. You may find this worksheet helpful. It’s important to note that for each new control method, it is possible to create a new hazard. Any new hazard created by a control must also be addressed.

Hierarchy of Controls Worksheet

Let’s practice implementing the hierarchy of controls with a hypothetical hazard: your workers are exposed to a noisy compressor on a regular basis.

1. Elimination: Is it feasible to complete the task without using the noisy compressor? What new hazards would this create?

2. Substitution: Is it feasible to replace the compressor with a new, quieter compressor? Are any potential hazards created by replacing the compressor?

3. Engineering Controls: Is it feasible to put the compressor in a separate room or muffle its sound with sound absorption material? What new hazards would arise?

4. Administrative Controls: Is it feasible to limit the time workers spend using the compressor? Do workers need to be trained or warned about the noise hazard?

5. PPE: Does a noise hazard remain after implementing all other feasible control methods? Which type of hearing protection should workers use? What hazards would hearing protection create?

Next Steps: Start with the most serious hazard you identified–the one that is most likely to cause severe injury or death–in your workplace. Work your way down the hierarchy of controls, applying controls from each level as feasible. Then move onto the next most serious hazard. Using this method, you will systematically correct each hazard you’ve identified.